NATIONAL FITTINGS CANADA (NFC)

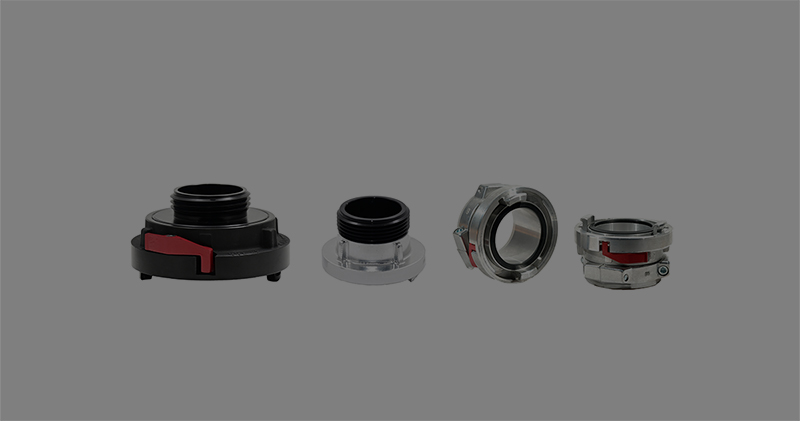

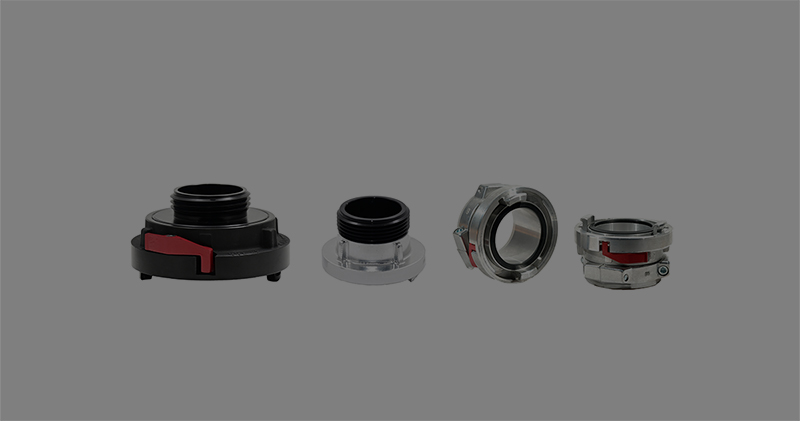

At NFC, we supply high quality Aluminum Hydrant Gate Valves shipping out of our warehouse the next day. We make it easy for you to purchase Hydrant Gate Valves in one location via our online store where we stock two models of HGV’s.

VIEW SPEC SHEET

USAGE

Hydrant Gate Valves are ideal for use in hose testing, hydrants, stand pipes and pumps. The HGV250 Series and HGV250-DS-Y Series are excellent shut-off vales used on the 2 ½” outlet port of hydrants to control water hammer and reduce hydrant main damage. Both Series are supplied with Full Flow Waterways and just 11 easy turns to open and close. Maximum operating pressure 250 PSI.

TERMINOLOGY

Casting is a process where the metal is melted before going into a mold. The metal pours into the mold and solidifies as it cools. The control of the molten metal temperature is critical. Likewise, the quality of the metal being melted must be controlled so that no impurities get into the molten metal.

Anodizing is an electronic process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

MATERIAL

HGV250 Series

Body cast from 356-T6 grade aluminum construction supplied hard coat anodized for corrosion resistance. Stainless Steel Spindle. Stainless Steel Ball Bearings and Set Screw. Hard Coat Anodized Gate, Swivel and Male Threads. Supplied with 3 Spoke Hand-wheel.

HGV250-DS-Y Series (Heavy Duty Yellow)

Body cast from 356-T6 grade aluminum construction supplied hard coat anodized with powder coat Vis Yellow body for corrosion resistance. Stainless Steel Spindle. Stainless Steel Ball Bearings and Set Screw. Hard Coat Anodized Gate, Swivel and Male Threads. Supplied with 3 Spoke Hand-wheel. Dual Seals on each side of Gate for seal proof shut off.

THREADS

NFC stocks all Canadian Provincial Fire Threads. Standard threads include BAT, WCT, CSA, QST, NSZ1, NH, NPSH, NPT.

|

STANDARD CANADIAN FIRE DEPARTMENT 2½" HOSE THREADS

|

|

SIZE

|

DESCRIPTION

|

ODM

|

TPI

|

|

2½"

|

AMA - Alberta Mutual Aid

|

2.990

|

8

|

|

2½"

|

BCT - British Columbia

|

3.000

|

8

|

|

2½"

|

BA (BAT) - Compatible with BCT & AMA

|

2.990

|

8

|

|

2½"

|

CSA - Canadian Standards Association - Ontario

|

3.125

|

5

|

|

2½"

|

QST - Province of Quebec Standard

|

3.031

|

7

|

|

2½"

|

Western Canada Fire Underwriters Association

|

3.250

|

6

|

|

2½"

|

Nova Scotia - Zone 1

|

3.234

|

5V*

|

|

2½"

|

Newfoundland -- (aka St. John's thread)

|

3.25

|

5V*

|

|

2½"

|

NST - American Standard Fire Hose -- USA

|

3.068

|

7.5

|

|

* It should be noted that most fire hose threads are blunt at the top -- but the 5V thread is cut to a sharp "V" point. To do this, the depth of the thread is 1/64th of an inch deeper than the conventional 5 threads-to-the-inch of the Canadian Standard Fire HoseThread.

|

NPSH – National Pipe Straight Hose. NPSH is sometimes referred to as “IPT” or Iron Pipe Thread. NPSH threads are straight threads and require a gasket for sealing between mating threads.

NPT – National Pipe Tapered. This thread is most commonly found in pluming applications. NPT is a tapered thread and the seal between mating threads is made by squeezing the threads together. Therefore, no gasket is required. NPT and NPSH threads are similar in diameter and threads per inch.

OPERATING PRESSURE

HGV Series and HGV-DS-Y Series operating pressure is specified at 250 PSI.

GASKETS

High quality swivel gaskets are lathe cut ozone free EPDM.

INSTRUCTIONS FOR MEASURING THREADS

If a thread gauge and caliper are not available, and a sample cannot be sent, the following method can be used to obtain the correct outside diameter and pitch of the thread needed.

- Cut a strip of paper about 1"(25mm) wide, long enough to wrap tightly around the circumference of the male thread and overlap at the ends.

- With a pin, pierce through both layers of the paper (fig.1).

- Press your thumb firmly against the thread hard enough to make a thread impression on the strip (fig. 2).

- Remove the strip and circle the pin holes on the strip with a pencil (fig. 3).

- Divide the distance between the pin holes by 3.1416. The result is the ODM (outside diameter of the male).

It is important that both the ODM and threads per inch (pitch) of the male part are given when ordering. Always include the paper strip with your correspondence. If not specified, "V" sharp thread will be furnished.

NATIONAL FITTINGS CANADA (NFC)

At NFC, we supply high quality Aluminum Hydrant Gate Valves shipping out of our warehouse the next day. We make it easy for you to purchase Hydrant Gate Valves in one location via our online store where we stock two models of HGV’s.

VIEW SPEC SHEET

USAGE

Hydrant Gate Valves are ideal for use in hose testing, hydrants, stand pipes and pumps. The HGV250 Series and HGV250-DS-Y Series are excellent shut-off vales used on the 2 ½” outlet port of hydrants to control water hammer and reduce hydrant main damage. Both Series are supplied with Full Flow Waterways and just 11 easy turns to open and close. Maximum operating pressure 250 PSI.

TERMINOLOGY

Casting is a process where the metal is melted before going into a mold. The metal pours into the mold and solidifies as it cools. The control of the molten metal temperature is critical. Likewise, the quality of the metal being melted must be controlled so that no impurities get into the molten metal.

Anodizing is an electronic process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

MATERIAL

HGV250 Series

Body cast from 356-T6 grade aluminum construction supplied hard coat anodized for corrosion resistance. Stainless Steel Spindle. Stainless Steel Ball Bearings and Set Screw. Hard Coat Anodized Gate, Swivel and Male Threads. Supplied with 3 Spoke Hand-wheel.

HGV250-DS-Y Series (Heavy Duty Yellow)

Body cast from 356-T6 grade aluminum construction supplied hard coat anodized with powder coat Vis Yellow body for corrosion resistance. Stainless Steel Spindle. Stainless Steel Ball Bearings and Set Screw. Hard Coat Anodized Gate, Swivel and Male Threads. Supplied with 3 Spoke Hand-wheel. Dual Seals on each side of Gate for seal proof shut off.

THREADS

NFC stocks all Canadian Provincial Fire Threads. Standard threads include BAT, WCT, CSA, QST, NSZ1, NH, NPSH, NPT.

|

STANDARD CANADIAN FIRE DEPARTMENT 2½" HOSE THREADS

|

|

SIZE

|

DESCRIPTION

|

ODM

|

TPI

|

|

2½"

|

AMA - Alberta Mutual Aid

|

2.990

|

8

|

|

2½"

|

BCT - British Columbia

|

3.000

|

8

|

|

2½"

|

BA (BAT) - Compatible with BCT & AMA

|

2.990

|

8

|

|

2½"

|

CSA - Canadian Standards Association - Ontario

|

3.125

|

5

|

|

2½"

|

QST - Province of Quebec Standard

|

3.031

|

7

|

|

2½"

|

Western Canada Fire Underwriters Association

|

3.250

|

6

|

|

2½"

|

Nova Scotia - Zone 1

|

3.234

|

5V*

|

|

2½"

|

Newfoundland -- (aka St. John's thread)

|

3.25

|

5V*

|

|

2½"

|

NST - American Standard Fire Hose -- USA

|

3.068

|

7.5

|

|

* It should be noted that most fire hose threads are blunt at the top -- but the 5V thread is cut to a sharp "V" point. To do this, the depth of the thread is 1/64th of an inch deeper than the conventional 5 threads-to-the-inch of the Canadian Standard Fire HoseThread.

|

NPSH – National Pipe Straight Hose. NPSH is sometimes referred to as “IPT” or Iron Pipe Thread. NPSH threads are straight threads and require a gasket for sealing between mating threads.

NPT – National Pipe Tapered. This thread is most commonly found in pluming applications. NPT is a tapered thread and the seal between mating threads is made by squeezing the threads together. Therefore, no gasket is required. NPT and NPSH threads are similar in diameter and threads per inch.

OPERATING PRESSURE

HGV Series and HGV-DS-Y Series operating pressure is specified at 250 PSI.

GASKETS

High quality swivel gaskets are lathe cut ozone free EPDM.

INSTRUCTIONS FOR MEASURING THREADS

If a thread gauge and caliper are not available, and a sample cannot be sent, the following method can be used to obtain the correct outside diameter and pitch of the thread needed.

- Cut a strip of paper about 1"(25mm) wide, long enough to wrap tightly around the circumference of the male thread and overlap at the ends.

- With a pin, pierce through both layers of the paper (fig.1).

- Press your thumb firmly against the thread hard enough to make a thread impression on the strip (fig. 2).

- Remove the strip and circle the pin holes on the strip with a pencil (fig. 3).

- Divide the distance between the pin holes by 3.1416. The result is the ODM (outside diameter of the male).

It is important that both the ODM and threads per inch (pitch) of the male part are given when ordering. Always include the paper strip with your correspondence. If not specified, "V" sharp thread will be furnished.